Refer IS:3177

Electric Overhead Travelling Crane

Hand Operated Travelling crane

Down Shop Lead. It is used for power feeding in equipment.

CT stands for Cross Travel and LT stands for Long Travel

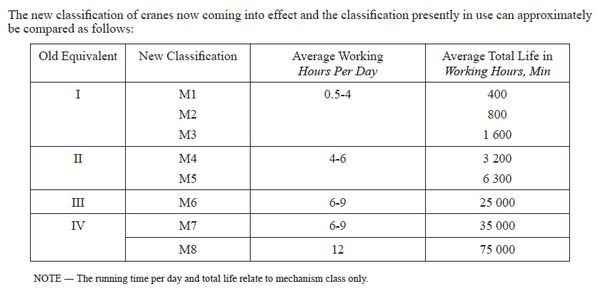

Its depends upon the class of duty and uses of the crane but generally we can consider life of cranes 25 five years if crane is class – II

Class – I Now M1, M2 & M3 Class – II Now M4 & M5 Class – III Now M6 Class – IV Now M7 & M8 as per IS:3177 2020.

Please refer to the above picture for the class of cranes — it’s basically selected on the basis of the usage of the crane.

class of EOT Cranes defines the usage of cranes, as seen above table different classes has different total life in working hours — so more the class the more is the life of the crane

Class of duty is decided based on the average working hours in a day (24hrs)- as mentioned in above table for class II duty average working hours is 4-6 hrs.

Class of duty indicates crane codal life and operation time for example if we consider class II duty crane it means Average Working Hours Per Day is 4-6 Hrs.

It depends on Crane Capacity, Span, lifting height, class of Duty and type of Crane.

Max capacity for a single girder crane can be 15T, however above 10T are not recommended by us. The Max Span we have manufactured is 28M for a single girder crane, however we won’t recommend beyond 20M

We have manufactured upto 28M span single girder crane – however the recommendation is not beyond 20M

Uses of slings depend on the object size and shape and also we have to take care of balancing of the lifted object. 2 leg may be used if the object is symmetrical shape, otherwise prefer 4 legged

Uses of slings depend on the object size and shape and also we have to take care of balancing of the lifted object. 2 leg may be used if the object is symmetrical shape, otherwise prefer 4 legged

Capacity of a sling should be min 2 times the load to be lifted if true vertical – please also refer if there is angle formed between the legs of the chain slings

Type of slings based on object shape and size. Capacity of slings recommended 2 times of the rated capacity. Also the capacity of slings depends on the lifting angle to be used for lifting the load. Refer fig below: for 1t load at an angle of 30degree, each strand is having tension of 0.52T, so a 2 leg legged 2T sling is required min. Whereas if the angle of lifting has to be 171degree then a 24T sling will be required to lift a load of 1T

For 10t crane the sling chosen should be min 20t (2 times the requirement to be lifted) also please refer to the angle chart for the decrease in the capacity of sling based on the angle of lifting

Depends on the angle of lifting also as shown in the above picture

Slings are of various types, 1) wire rope slings, 2) chain slings 3) synthetic web slings.

synthetic slings are used in case of light and delicate loads and where changes of scratch marks etc are to be avoided. Being very light weight they are easy to rig, flexible. Being flexible they take the shape of the laid lifted and does not cause much damage to the surface. synthetic slings cannot be repaired and have to be discarded completely in case of damage

Wire slings and chain slings : wire slings have the advantage that any breakage of the rope is visible and hence the chances of accidents are less, however chain slings the chain will break immediately without any warning sign. However shain slings are easier to handle compared to wire rope slings

2 legged slings should be used if the laid is symmetric, and 4 legged in case it is a-symmetric.

The ends of the slings are chosen as per the application as to whether ring is required or a hook is required at the end of the slings

Material is either nylon or polyester. No the capacity cannot be compared as such , however their self weight to lifting ratio is much higher.

Electric Hoist suspended and run in a single fixed I-Beam section and have only two motion upward downward and left and right in one axis.

Single Girder Crane– It is a type of EOT crane having one Girder and two nos of end-carriage an electric Hoist suspended from the crane girder. It allows three direction motion- upward downward, left to right along with span and backward forward along with length of shed.

Double Girder Crane– It is a type of EOT crane having two nos of Girder supported with two nos of end-carriage.. It allows three direction motion- upward downward, left to right along with span and backward forward along with length of shed. In double girder crane crab or trolley with hoisting and ct mechanism travel over the bridge girder.

For better visibility of the moving part. Also defined in factory act

There is a lateral (horizontal) force on the wheels when the flange touches the rail. Ball bearings are not designed to take lateral loads and can take only the vertical loads, hence spherical roller bearings are preferred, specially for higher capacities.

Alignment of LT Gearbox with Wheel and LT Motor is very important. flexible gear coupling are used to tackle the alignment. However nowadays direct mounting on the wheels have been started to remove any alignment problems through geared motor concept. This works much better

They are defined in section 29 of Factory act 1948, — there are many things mentioned in the same and the competent engineer of our state will be able to guide about the certifications, tests and records which needs to be maintained both for lifting machines and lifting tackles. Most importantly all the cranes and hoists should be tested every year for the SWL

Wheels attached with a driving arrangement (Gearbox – motor) are called driving wheels and wheels are not attached to the gearbox- motor and rotate idly as an idle wheel.

Please find download from the internet it is available free of cost.

Speed of LT and CT should be kept around 20 mpm for a pendant operated crane because a person can walk comfortably at these speeds. And the chances of accidents are also less. In case of radio remote or cabin operated cranes you can take the LT speeds to upto 50 mpm, but Ct speed maximum should be kept at 20 mpm only. In expectation cases it can be more also but not recommended.

Higher speeds of LT can be taken only in cases when the bay lengths are very long and load lifted is stable.

Colour of all overhead moving parts have been written in Factory act to be golden yellow with Zebra lining at the ends. It is done for more visibility.

Depends on the Span of the Crane also

They are defined in IS:3177, however as users you should not be worried about the same

Goliath cranes can go upto 500T also. As such no limit

The size calculation is defined in IS clearly – in depends on the wheel load, and the rail flange width and the travel length

The size calculation is defined in IS clearly – in depends on the wheel load, and the rail flange width and the travel length

Permanent deformation happens if one overloads the crane. Positive Camber is good for a crane, however negative camber is not desired at all

Rotary limit switch has gears inside them – one of the reasons is that those gears have worn

Yes you can do and you must do yearly, better get it inspected by the competent engineer in your state as it is a statutory requirement

Diameter of Rope of a 5t crane also depends on the number of falls, construction of wire rope, tensile strength of wire rope.

No if it’s happening then there is a problem in alignment. Which leads your wheel wear out also rail section.

Wire rope has to be lubricated every quarter — however it also depends on the usage and the atmosphere — in case it is coastal area, or extreme temperatures then frequency may be increased

Cadmium compound

It’s because the wire rope while wounding is having some twist, the best way is to unwound the full wire rope and lay it on floor and check for any twist and remove the twist and then wound again on the hoist. If the twist is not removed — then we need to replace the wire rope

kink Formation, starts first with the formation of a loop when the wire rope is in unloaded condition or lying loose on floor (ie. the bottom block is resting on floor) and then when the loop tightens when pulled up forming kink. The loop should immediately be removed by turning the rope in other direction, to avoid kinking

It is a statutory requirement to get the cranes inspected once in 12 months by a competent engineer

Wire ropes are made up of steel of various grades

Lubricant for wire rope is cadmium compound and frequency is every quarter, however frequency can be increased depending on on the environment and usage

Load test certificate is provided by competent engineers of the concerned state only. as this is a statutory requirement laid down in factory act

Any brand – -use cadmium compound

Probable cause is alignment of the DSL system

Discard the wire rope if the diameter is reduced by 8-10%. Or if 1 in 5 strands are broken

RRC stand for Radio Remote Control

No there is no frequency defined for wire rope replacement — you have to check the physical condition of the wire rope ie 1) broken wire ropes, 2) reduced dia 3) distortion – like kinking

Not required or defined anywhere – discard wire rope only if broken wires, reduction in diameter, or other physical damage or abnormality as defined in the picture

Please refer the discard criteria of ropes

Not required. wire rope will elongate and the diameter will reduce– hence no need to check in elongation – which is difficult to check — just check the diameter — if it is 10% less then discard

Tensile strength of wire rope is not required to be tested, please follow the discard criteria of the wire ropes

Brake Pads are in important safety item and should be procured either from Crane Manufacturer or the Brake manufacturer only

Maximum allowed deflection of crane depends on the span of the crane — irrespective of the capacity of the crane. allowed maximum deflection may be taken as span/900 at full load at the center of the crane span.

- The gearbox ratio is different on each end. Check the rpm of the LT wheels, on both the end.

- The motor RPM are different

- The coupling in between the Gearbox and wheel or between the gearbox and motor has certain play — hence one LT wheel moves prior to the other

- Load is always lifted at one end of the crane :if the load is always lifted at one end of the span — then it will result in extra load on that side crane and hence the LT wheels will be loaded more and will wear more, hence reduction in the LT wheel diameter of that side, in respect to the other side.

so the skewing effect will be seen if the LT wheel diameter is reduced at one end. its best to replace tall the LT wheels in that case as skewing may result in a crane accident - Runway rail – are not aligned or there is difference in heights of the 2 gantries

Also the crane diagonal may be not correct. You can check that by moving the crane in one direction then the one side flange will touch and on the other side other side flanges will touch

IS: 4460 is general code for all the gearboxes. For cranes prefer hardened and ground helical gearbox with parallel shafts, gear pinions should be made from low carbon alloy steel and case carburised to 55-60 HRC. Since the Cranes have impact loading every time it lifts the material so the above combination best suits the application.

Reva Gives LT Wheels and Shafts as Shrink fit, there are no keyways in the same — hence it is a interference fit

For single girder cranes we provide maintenance cabin at one end of the crane span and the panel is mounted in this cabin, your manufacturer to provide the same. also incorporate in your specs in case you are taking new cranes

Min deflection is not defined in any code– MAX deflection is defined — and above that deflection if the crane is deflection then it means that crane is not designed properly.

There is no authorised certification authority, you can give the internal certificate, after training him the signals and the crane operations

Life of wire rope is defined by the physical damage, distortion and the atmosphere

Factor of safety is defined in is:3177 — it is different for wire rope, main motor, lt motor, ct motor, brakes and steel to be used for the girder section etc

There is no term like this — it is only the class of duty of crane– also the FOS is for the designers not for the users — if you are having a 5t crane then the max load you can lift is 5t only. Although IS:3177 mentions that the testing of the crane shall be done on 125% — but that does not mean that the crane can be loaded and operated at 125%. Further the class of duty defines the usage of the crane and not the capacity of the crane. So it does not mean that if i have 5t crane of class 4 duty then i can lift 6t with it.

As per is 15419:2004 boom deflection is boom length/250.And column+boom permissible deflection id column+boom length/300

The permanent deformation should not be 0.5% more than of the original distance or the hook opening.

Material of hooks is defined in is:15560 — there are grades of hooks (L,M,S,T) and the material of hook depends on the grade of the hook –for IS:15560 — please refer https://archive.org/details/gov.in.is.15560.2005/page/n9/mode/2up

Please check the dsl installation alignment

Please check the dsl installation alignment

For the weight of the crane — span, lift, capacity, class of duty is required

Thrustor brake awaj karne ka reason – alignment ka hain

Avoid 220V for pendant. Proper ground of earring wire and not exceed from 1Mga oms earthing resistance.

Please download ebook from the this location for detailed inspection checks recommended https://www.revacranes.com/periodic-inspections-of-eot-cranes/

Please download ebook from the this location for detailed inspection checks recommended https://www.revacranes.com/periodic-inspections-of-eot-cranes/

Ground to bus bar to crane rail, platform, Panels motors, brakes and all other electrical equipment. Ensure two earthing points on every electrical part.

Regular visual inspection and spraying of kerosene oil if honey bees start honeycombing.

Leading parameters of Crane are:- Capacity—> maximum working load of job weight

Span—-> Center to center of LT Track

Total lift—->Maximum upward position of Hook from above floor level+Below floor level

Class of duty—–>Define approximate life of crane

Type of crane—–> Single Girder or Double Girder

Operation mode——> Pendant /Cabin/RRC

Speed of crane——>Rotational motion of crane i.e. Upward Downward, Left Right, Forward Backward.

VVFD—–> Electrical control device stands Variable Voltage Variable frequency

Travel length—–>Longitudinal distance of shed or track

Location of crane—->Indoor / Outdoor

Area ——> safe or hazardous.

Please refer BS:466 appendix F , span variation permissible is +-3mm upto 15m span and beyond that 3 + 0.25*(span-15)

Take a washer of 4mm and maintain the distance by moving the rails forward, with time the rails intend to shift from their positions, also it is good idea to add stoppers on the sides of the rail, so that the rail does not shift, and also provide end stoppers

Upto 4mm wear is acceptable (although it is not written in any code) — however if there is local reduction on a part of the rail then it should be replaced locally. Please check that the rail difference at the join is not acceptable

No please dont use different sizes of rail, please make sure that the height of rail is same before they are being installed

Yes the wheel flanges will touch the rail, in a zig zag manner , means that the flange of one side will touch once and then the other side of the wheel flange should touch. Ideally however the wheels flanges

Channel on top of gantry girder is a required as per the structural calcualtions, as when the crane moves aprat from vertical forces it also produces horizontal forces, for the gantry to be able to take horizontal forces a capping channel is provided on top of the ibeam.

Square bars are much cheaper than rails and find their usage specially in small capacity upto 10t the Rails sections are not required. Also advantage of square or rectangular bars is that they can be welded easily onto the gantry girder, and hence will not shift from their location for years to come.

Rails on other hand are more preferred in case of cranes higher than 10t capacity and the span more than 20 M. The advantage is that in case the layout is not correct, then they can be rectified easily.

No span of a crane is dependent on the building width, the more is the building width the more is the span. Normally only 500-1000mm on each side of the building is left for maintenance platform , the rest is the span

Track alignment can be checked with a piano wire and there are some laser devices also available for checking

Track alignment can be checked with a piano wire and there are some laser devices also available for checking

As far as possible this should be zero tolerance in this – as this is one of the biggest reasons for the wheel and wheel bearing damage. We even prefer that the rail join should be cut at an angle so that at any point the complete joint is not on the wheel

Replacing of wheel is necessary only when there is more than 5% difference in the wheel diameters — in case all the wheels have reduced diameter equally — then there is no need of replacements. Do remember that in case you are replacing the wheel, replace all the wheels simultaneously

Max 5% difference may be taken beyond which the crane will start skewing. However the reason for the one wheel getting additiona wear should be studied. Also if there is difference in the diameter replace of all the wheels or turn the diameter of all the wheels to make them equal size

Wheel diameter ek side kam hain, ya gearbox ka reduction barabar nahi hain , yo lt motor ke rpm same nahi hain. (either wheel diameter is less at one end, or gearbox reduction is different or motor rpm has a problem or in last case diagonal of crane is not accurate)

No the tools are the normal tools like spanners, allen keys, grease guns, screw drivers, hydraulic jack etc, piano wire, multimeter, megger etc

Steel tape, ultrasonic or laser distance measurement instruments. Please ensure not to use fibre tapes suitable material of wheel? c55mn75 is the material of the wheel

Intermittent welding should be done on either side of the weld 500MM gap with 100MM welding length, with min 6mm weld

315 -350 BHN

Wheel diameter can be measure with caliper gauges and vernier

No there is no such guideline — but it is imperative — rail disallignement – can even lead to crane derailment

Internal defects can be found by UT (ultra sonic testing)

en353 is better for making gears

Heardness of gear for low carbon alloy steel gear pinion should be 55-60hrc

Shaft can be of en8, en9 or en18 if the pinion is not there on it, in case the shaf tis the pinion then go in for EN353

Please mention the proper method for checking coupling alignment during refitting after dismantling?

Rotate the motor shaft coupled with gearbox by hand, install a dial gauge on the shaft, and check if there is any deviation

Check all parameters one by one and operation also.

Refer discard criteria for the wire ropes

The degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and water.

Refer discard criteria for the wire ropes

BOTH BRAKES ARE FAIL SAFE ITS DEPEND ON REQUIREMENT

FOR DC DISC TYPE BRAKE WE WILL USE RECTIFIER FOR CONVERTING THE POWER AC TO DC

Min 1.5sq.mm to 2.5sq. Mm max for control cable. For power cable as per power load calculation.

Yes, transformer should be used for thrusters

Plus minus 10% of rated speed. If speed beyond the tolerance limit there is malfunction in equipment.

No we don’t have any distributor but we have regional office and you can directly send requirement to us

Our email id is [email protected] [email protected] [email protected] [email protected] [email protected] [email protected]

A.K.DWIVEDI :9650391334

North Region : Mr T.K. Sharma P: +919958998427 Escalate : 9650391334

South Territory Sales : Mr. Moinuddin P: +919899484751 Escalate : 9650391334

If drive is used in your crane then check CT parameter for speed if without vfd then kindly check your brake setting and mechanical arrangement.

Depends on VVVF Model, best it can be suggested by the VVVF Drive manufacturer

AC & DC both types are available

Please check with E105 for input feeding and then output.

Check all electrical connections

There is a delay issue between Motor and the braking Thruster motor, How to solve in LT, CT & Hoist?

Need proper adjustment of the brakes.

Both are the same.

Reset the drive and put again parameters.

Find over current in drive display. Reasons– Brake not adjusting properly.

Take motor data from motor nameplate and fill all details in drive for auto tuning.

Variable voltage variable frequency Drive —VVFD stands also we say VFD in short form

Misalignment , loose fitting and improper keying.

IS 3177:2020 for recommended formula.

Customer Query on Semi EOT crane for ASH system A/c Dr.NTTPS

1. Any IS STD reference which quotes semi EOT is a mix of electrical operation (motor operated) & mechanical operated (chain pulley block), If any. Plz share the same.

Reply : Please note that EOT Crane is a fully customised product based on the application, no. of operation, type of loading, atmospheric requirement, utilisation, required life hours etc.

Crane have majorly 3 motions & if any motion out of 3 is manual than crane will be Semi EOT Crane. Based on the required pulling effort, any motion can be selected manual subjected to a man pull 250N continuously & 350N for a short period. In general Traverse motions required less pulling effort hence

Cross travel & Long travel motions preferred worldwide for manual operation subjected to a man pull 250N continuously & 350N for a short period.

However for the lower rated load hoisting also can be selected for manual operation.

IS:3177 & IS: 3938 will be applicable for the relevant integral items selection & design.

2. What is the limitation in semi EOT to go with electrical driven movement. (Min/Max span) for e.g if the span is above 10m we are going ahead with electrical operation likewise is there any limitation for long travel?

Reply : Any motion can be selected for manual operation subjected to a man pull 250N continuously & 350N for a short period.

3. Customer requires (wishing) motor drive for long travel.

Reply : Can be offered with additional price for relevant changes(cost difference is very small). However if the operational requirement is not continuous & Crane Capacity is upto 10T subjected to Crane Span max. upto 12M manual operation can be selected.

Customer Query on Semi EOT crane for ASH system A/c Dr.NTTPS

Please note that EOT Crane is a fully customized product based on the application, no. of operation, type of loading, atmospheric requirement, utilization, required life hours etc.

Crane have majorly 3 motions & if any motion out of 3 is manual than crane will be Semi EOT Crane. Based on the required pulling effort, any motion can be selected manual subjected to a man pull 250N continuously & 350N for a short period. In general Traverse motions required less pulling effort hence

Cross travel & Long travel motions preferred worldwide for manual operation subjected to a man pull 250N continuously & 350N for a short period.

However for the lower rated load hoisting also can be selected for manual operation.

IS:3177 & IS: 3938 will be applicable for the relevant integral items selection & design.

Any motion can be selected for manual operation subjected to a man pull 250N continuously & 350N for a short period.

Can be offered with additional price for relevant changes(cost difference is very small). However if the operational requirement is not continuous & Crane Capacity is upto 10T subjected to Crane Span max. upto 12M manual operation can be selected.