Handling

Improper handling or coiling of rope from reels or coils often results in the “springing” of strands and kinking of the rope both of which are very difficult to be corrected It reduces the effective rope life considerably.

If the rope is supplied on a reel, it should be mounted on a shaft and rope laid off from the reel while it rotates. Suitable brakes should be applied on the flanges of the reel. If the rope is supplied in large coils, these should be mounted on a turn-table with suitable brakes and the rope paid off while the turn “table rotates “ Small coils of wire ropes can be made to roll along with the ground for uncoiling Rope should neither be pulled straight from the coil while the coil rests on the ground nor taken off turn by turn from reel while it is lying on its flange on the ground also never allow the reel to rotate at high speed (i.e. exceeding 2 km per hour at any time) during pay off.

Kinks

The wire ropes are damaged due to improper handling. The most common form of damage is kink Formation, which starts first with the formation of a loop as Illustrated and then the loop tightens when pulled up forming kink The loop should immediately be removed by turning the rope in other direction.

The illustrations show stages of kink-formation.

a) How a kink starts

b) When pull gets on further damaged is done

c) When kink is straightened. The wires may or may not be broken but the damage is done and when rope is put to service. Wires will quickly break

Never use a rope that has been kinked unless the kinked portion is removed.

Inspection of Wire Ropes in Use

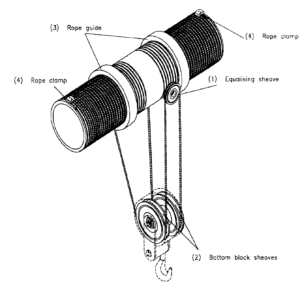

Inspection of a rope in use is essential at regular intervals to observe the presence of excessive wear on the outside wires resulting in marked reduction of rope dia. broken wires corrosion and pitting, state of Lubrication, core condition, etc.

The reduction in diameter of a rope is generally due to excessive wear of outside wire and bedding-in. In case of a fiber cored ropes. However. marked reduction in rope diameter should be thoroughly investigated and its cause determined.

In case of broken wires, their number and distribution should be taken into account to calculate their effect.

The inside wires and core can also be damaged due to lack of lubrication, Where corrosive conditions exist. these should be controlled by correct and timely lubrication.

Rope Care

=> Do not allow your rope to be stored in a damp or open place This causes deterioration of rope and fiber core.

=> Do not let your rope be mishandled when uncoiling or unreeling. This causes kinks to form.

=> Do not cut a rope before it has been sized-even if it is a preformed rope. The lays can become loose.

=> Do not use a rope that is not flexible enough for the size of your drum and pulleys. This causes bending fatigue.

=> Do not operate your rope on sheaves and drum with worn out grooves and broken flanges. This damages the rope.

=> Do not subject the rope to severe overload and sudden jerks. This causes severe damage to rope and Shortens its life.

=> Do not load a rope beyond its safe working load. Reduction of safety factor may jeopardize not out your rope, but also your equipment.

=> Do not allow your rope to get dry and thereby corrosion setting in. Lubricate it with the best quality lubricant and at regular intervals.

=> Do not forget to check the conditions of our rollers, pulleys drum and sheaves. The rope life depends very much on the conditions of these auxiliaries.

It is of utmost importance that proper care is taken in handling, fitting and maintenance of your rope.

When to Change a Rope

A close examination and regular inspection of rope will indicate if a new rope is to be put in. Following are the guiding factors for parting in a new rope:

* When the number of visible broken per cracked wires exceeds 10 per cent of total number of outer wires within “one rope lay“.

* When wear on outer wires exceeds one-third of their diameter

* When the loss in effective metallic area in the form of broken/cracked wires along with wear on outer wire exceeds 10 per cent.

* When gradual loss in rope strength due to wear or corrosion or both exceeds 1/6th of the original rope strength.

* When corrosion on wires show noticeable pining and loosening of wires.

* When rope gets deformed or distorted and the affected portion cannot be cut out.

However, the experience of the ropeman and statutory regulations are the final words as to when a rope to be changed.

Insist your crane vendor to provide you with the 8 wheel configuration crane, which will have more contacts on the gantry girder and hence the size of the gantry girders will reduce.